Manufacturing in the AR Era: Improving Efficiency and Productivity

The AR Era has revolutionized the way that manufacturing works. By using augmented reality AR in manufacturing can significantly improve efficiency and productivity in their processes. AR enables manufacturers to use data-driven insights to make decisions faster and more accurately. In this blog post, we will explore how AR can improve efficiency and productivity in the manufacturing process. We will examine the available AR technologies and how they can streamline operations, reduce costs, and increase output.

Introduction

With the rapid pace of technological advancements, industries are experiencing a transformational shift. The manufacturing sector, which has relied heavily on manual labour, is now turning to augmented reality (AR) to improve productivity and efficiency. AR is no longer just a technology used in video games; it has a practical application in various industries, including manufacturing. In this blog post, we will explore the current state of AR in manufacturing, its benefits, and its potential future applications. We will also examine the need for technological advancements in manufacturing and how AR contributes to meeting those needs.

The current state of AR manufacturing

Augmented Reality (AR) is transforming the manufacturing industry by improving the efficiency and productivity of operations. Technology is changing the way manufacturing processes are designed and executed. According to a report by MarketsandMarkets, the global market for AR in manufacturing is expected to grow from $609 million in 2020 to $1.18 billion by 2025.

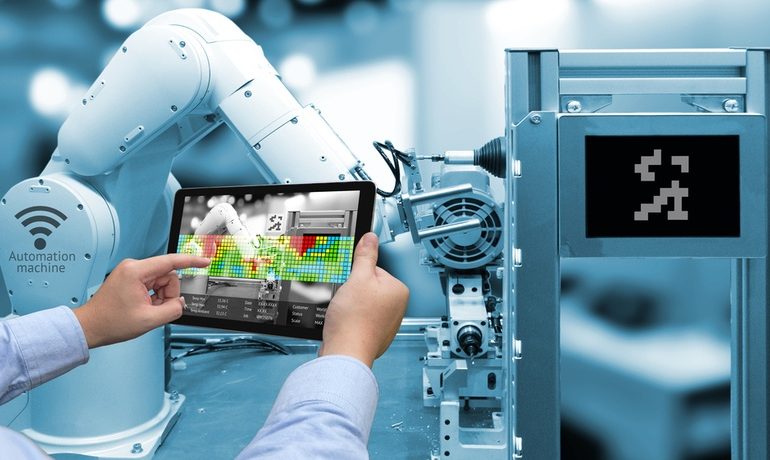

AR in manufacturing is already used for various applications such as remote collaboration, training, quality assurance, and maintenance. Companies use AR tools such as smart glasses, head-mounted displays, and mobile devices to improve their processes and operations. These devices provide workers with real-time information and virtual instructions, enabling them to perform tasks more precisely and efficiently.

The current state of AR manufacturing is focused on providing workers with real-time access to critical information, improving training processes, and reducing downtime. The technology is helping companies improve their overall productivity by reducing errors and streamlining operations. AR is being integrated into various stages of the manufacturing process, from design to delivery.

Despite the benefits of AR manufacturing, there are still challenges to its adoption. The technology is still relatively new and expensive, and many companies must invest boldly. Additionally, there are concerns about the privacy and security of data generated by AR devices.

However, as technology advances and becomes more affordable, we can expect to see more companies adopt AR in their manufacturing processes. AR is poised to revolutionize the manufacturing industry by improving operations’ speed, accuracy, and safety.

What is the need for technological advancement?

In today’s fast-paced business world, technological advancement has become a necessity for manufacturing companies. It is essential to keep up with the changing trends and meet the increasing demands of consumers. Additionally, several other factors make technological advancement a need in manufacturing.

Firstly, more than the traditional manufacturing methods are needed to meet the current market demands. Consumers today expect products that are high in quality and customizable to their preferences. These requirements are challenging to fulfill with traditional manufacturing techniques.

Secondly, modern manufacturing processes require greater accuracy, efficiency, and productivity. With the advancement of technology, there is an increased need to integrate systems and automate processes to reduce the scope for human error. This is especially true in industries that require repetitive tasks that can cause fatigue, boredom, and even injury.

Lastly, technological advancements are critical in maintaining a competitive edge in the global market. Companies that do not invest in technology and innovate are likely to fall behind their competitors and eventually become obsolete.

How is AR being used in manufacturing?

The use of AR technology in manufacturing is increasing. From designing and testing prototypes to maintenance and repair work, AR is transforming how manufacturers approach their work. Here are some ways AR is currently being used in manufacturing:

- Training and Education: AR technology provides an interactive and immersive experience for trainees to learn and practice new skills without risking harm. The technology also allows trainees to visualize complex machines and processes realistically.

- Assembly and Maintenance: With AR technology, technicians can access digital overlays that display crucial information on a device. The overlay shows how parts fit together, what tools are needed, and where to locate parts. This speeds up the process of assembly and reduces errors.

- Quality Control: AR can provide quality control by identifying defects and anomalies in manufactured products. AR technology allows for a more detailed product inspection than traditional methods.

- Product Design: AR technology can be used to create and modify 3D models of products. This enables manufacturers to visualize how the product looks and functions in real-world situations. AR can also test different product designs before finalizing the product.

Overall, AR technology is used in manufacturing to increase efficiency and productivity and reduce errors. It has the potential to revolutionize the way manufacturing companies work.

Benefits of AR manufacturing

There are several advantages to using AR technology in the manufacturing industry. One of the primary benefits is increased efficiency and productivity. With AR, workers can access critical information in real time, reducing the need for physical manuals or time-consuming research. This, in turn, reduces the likelihood of errors and downtime.

Another significant advantage of AR in manufacturing is improved quality control. Using AR technology, workers can identify issues earlier in manufacturing, reducing waste and minimizing defects. AR can also give workers a more intuitive understanding of complex manufacturing processes, leading to better decision-making and problem-solving.

AR manufacturing also enables remote collaboration. This means that employees can work together, regardless of location, reducing the need for travel and costly in-person meetings. Additionally, remote collaboration facilitates knowledge sharing and leads to more effective teamwork.

AR technology can also enhance worker safety. With AR, workers can access critical safety information in real time, reducing the risk of accidents or injury. AR can also enable workers to practice complex or dangerous tasks in a virtual environment, reducing the risk of accidents during training.

Overall, the benefits of AR in manufacturing are significant and wide-ranging. By improving efficiency, productivity, quality control, collaboration, and safety, AR technology can help companies stay competitive in a rapidly evolving marketplace. As the technology continues to grow, we can expect even more exciting and innovative applications.

Potential future applications

While AR technology already impacts the manufacturing industry, many potential future applications could improve efficiency and productivity.

One area where AR could be utilized is in training new employees. AR technology can provide a hands-on experience without physical equipment or materials, allowing for more cost-effective and efficient training programs.

Another potential application is in the field of predictive maintenance. AR could provide real-time data and alerts to maintenance personnel, allowing for quicker identification and resolution of issues before they escalate into more severe problems.

AR could also be used to enhance collaboration between teams, both within a manufacturing facility and across multiple locations. Teams could use AR technology to share information, collaborate on designs, and work together more efficiently, regardless of physical location.

Overall, the potential applications for AR in manufacturing are vast and varied. As technology continues to develop, we can expect to see even more innovative ways to improve efficiency and productivity in the manufacturing industry.

Conclusion

Manufacturing in the AR era is changing the face of the manufacturing industry. It offers numerous benefits, such as improved efficiency, productivity, and accuracy. With AR technology, manufacturers can optimize their processes, enhance the quality of products, and save time and money.

Moreover, AR manufacturing also opens up a world of possibilities for future applications. From remote troubleshooting to virtual training and immersive customer experiences, the potential for AR in manufacturing is endless.

The manufacturing industry must continue embracing technological advancements like AR to remain competitive and relevant in today’s market. With the help of AR technology, the manufacturing industry can look forward to a brighter future with improved efficiency, higher productivity, and a more engaging workforce.