Streamlining Complex Assembly Processes with AR

As the complexity of assembly processes continues to increase, manufacturers are looking for innovative ways to streamline their operations. One potential solution is to leverage augmented reality (AR) technology. AR can provide assembly workers with an interactive, 3D view of the assembly process, enabling them to quickly and accurately complete tasks while minimizing the need for rework. In this blog post, we will discuss how AR can help to streamline complex assembly processes. We will also explore the benefits of utilizing AR for assembly and the various applications of this cutting-edge technology.

How can AR provide real-time guidance and visualization?

Augmented reality (AR) revolutionizes complex assembly processes by providing real-time guidance and visualization. AR technology overlays digital information in the real-world environment, enhancing the worker’s perception and understanding of the task at hand.

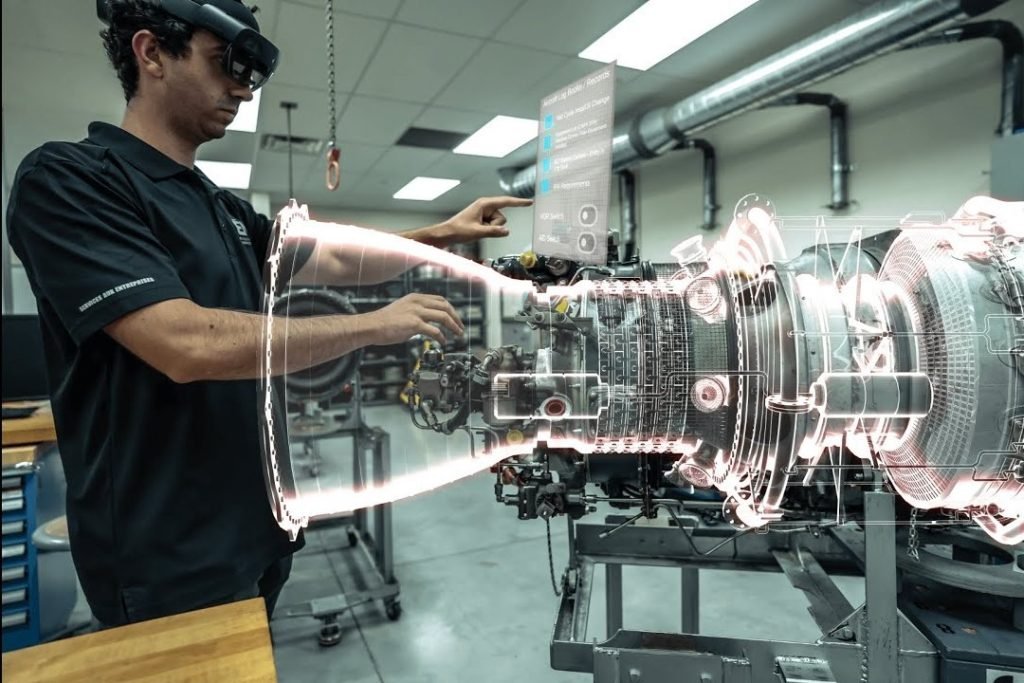

Through AR headsets or smart glasses, assembly workers can receive step-by-step instructions directly in their field of view. This eliminates the need for printed manuals or separate screens, enabling workers to focus solely on tasks without distractions. AR can guide workers through the entire assembly process, showing them where each component should be placed, which tools to use, and in what sequence the steps should be carried out.

Moreover, AR can provide real-time visualization of the final product. This means that workers can see how the assembled machinery or equipment will look even before the process is complete. This visualization helps ensure that the assembly progresses correctly and that errors or misalignments are detected and corrected immediately.

AR also enables workers to view the internal components of the machinery or equipment without physically disassembling it. This can be especially helpful in troubleshooting or maintenance scenarios, where identifying faulty components or understanding the inner workings of a complex system is critical.

Overall, AR’s real-time guidance and visualization capabilities significantly enhance assembly processes. AR is streamlining complex assembly processes like never before by reducing errors, improving efficiency, and increasing worker productivity.

The Role of augmented reality in assembly processes

Augmented reality (AR) has revolutionized various industries, including assembly processes. The Role of AR in assembly processes is crucial as it provides real-time guidance and visualization for workers. By overlaying digital information in the real-world environment, AR enables workers to understand the assembly process comprehensively.

AR technology allows workers to see virtual step-by-step instructions, images, or animations directly on the assembly components, reducing the need for printed manuals or training materials. This real-time guidance helps workers navigate complex assembly tasks, ensuring accuracy and efficiency.

Furthermore, AR enhances collaboration among assembly teams. With AR-enabled intelligent glasses or mobile devices, workers can remotely communicate and share their views with colleagues or experts. This real-time collaboration saves time and improves problem-solving, reducing the risk of errors and delays.

Another role of AR in assembly processes is quality control. AR technology can provide real-time feedback on the accuracy of each assembly step, reducing the chances of mistakes or defective products. By visualizing potential errors or mismatches, workers can rectify them immediately, preventing further complications.

Overall, the Role of AR in assembly processes is to streamline complex tasks, improve accuracy and efficiency, enhance collaboration, and ensure quality control. As AR continues to evolve, its impact on assembly processes is set to increase, transforming traditional methods into more innovative and effective practices.

Benefits of using AR in assembly processes

Using augmented reality (AR) in assembly processes offers numerous benefits that can significantly improve efficiency and accuracy. One significant advantage of using AR is that it provides real-time guidance and visualization to workers, enabling them to understand complex assembly steps more easily. With AR, workers can see virtual overlays on the physical equipment or machinery, which provides clear instructions on the exact locations of components, connections, and adjustments. This reduces the need for paper manuals or constant supervision, saving time and minimizing errors.

Another benefit of AR in assembly processes is identifying errors and inefficiencies early on. AR can detect incorrect placements, missing components, or assembly mistakes in real time, allowing workers to correct them immediately. This helps prevent costly rework or potential safety issues down the line. Moreover, by providing instant feedback on assembly accuracy, AR enhances quality control and ensures all components are correctly assembled.

AR also improves worker productivity by reducing training time and enhancing skill development. With AR-guided assembly processes, new workers can quickly learn complex tasks, as the virtual overlays provide step-by-step instructions and highlight crucial areas. This minimizes the reliance on experienced workers and expedites the onboarding process.

In summary, the benefits of using AR in assembly processes include:

- Improved accuracy.

- Reduced errors and inefficiencies.

- Enhanced worker productivity.

- Accelerated training and skill development.

Implementing AR technology can revolutionize assembly processes, making them more efficient, precise, and cost-effective.

Errors and inefficiencies in assembling complex machinery or equipment

Making complex machinery or equipment can be challenging, requiring careful attention to detail and precision. However, errors and inefficiencies are bound to occur due to the complexity of the assembly process. These errors can range from minor to critical failures that can result in costly repairs or safety hazards.

One common source of errors is the need for more precise and accurate instructions. Traditional paper manuals or 2D diagrams can be confusing and challenging to follow, leading to incorrect assembly. Additionally, the sheer complexity of the machinery or equipment can make it easy to miss necessary steps or connections.

Another primary source of errors is human error. Even with the best training and expertise, human beings are prone to making mistakes. Fatigue, distractions, or even a simple lapse in concentration can lead to errors during the assembly process. These errors can have a ripple effect, causing further complications down the line.

Inefficiencies can also arise from the time-consuming nature of traditional assembly methods. Workers may spend significant time searching for tools or parts, resulting in delays and reduced productivity. Specific tasks may require multiple workers, leading to unnecessary coordination and communication challenges.

Augmented reality (AR) technology can address and minimize these errors and inefficiencies. AR can help workers assemble complex machinery or equipment accurately and efficiently by providing real-time guidance and visualization. AR overlays digital information onto the physical world, giving workers clear and intuitive instructions. This eliminates the need for complex paper manuals and reduces the chances of errors due to confusion or misunderstanding.

AR also improves assembly accuracy and efficiency by providing real-time feedback. For example, AR can highlight potential errors or missing connections, alerting the worker before it becomes a significant issue. AR can also provide step-by-step instructions, guiding the worker through the assembly process logically and systematically. This helps reduce the chances of missed steps or connections.

Overall, AR offers a powerful solution for streamlining complex assembly processes. By addressing errors and inefficiencies, AR improves assembly accuracy and efficiency, saves time, and reduces costs. AR is an invaluable tool in today’s industrial landscape, potentially revolutionizing how we assemble machinery and equipment.

How can AR provide real-time improving assembly accuracy and efficiency?

Augmented reality (AR) has emerged as a game-changing technology in various industries, and assembly processes are no exception. With its real-time guidance and visualization ability, AR has revolutionized how complex machinery or equipment is assembled.

One of the key ways in which AR improves assembly accuracy and efficiency is by overlaying digital information onto the physical workspace. By wearing AR-enabled glasses or using a handheld device, assembly workers can see virtual instructions and annotations superimposed onto their working parts. This eliminates the need for paper instructions or constantly referring to a computer screen, significantly reducing errors and assembly time.

AR also enhances efficiency by enabling remote collaboration. With AR, experts can virtually guide assembly workers in real-time, regardless of location. This eliminates the need for physical presence and expedites troubleshooting and problem-solving during the assembly process.

Furthermore, AR can provide step-by-step instructions and animations, simplifying complex assembly procedures. Assembly workers can visualize each part’s exact positioning and orientation, minimizing the risk of misalignment or incorrect installation. Real-time feedback and alerts can also be integrated into the AR system, ensuring immediate detection and correction of any mistakes or deviations from the assembly process.

Overall, AR significantly improves accuracy and efficiency by streamlining complex assembly processes with real-time guidance and visualization. It empowers assembly workers with the necessary knowledge and information, enhancing productivity and reducing costly errors. As technology continues to evolve and become more accessible, we expect to see even greater adoption of AR in assembly processes, ultimately revolutionizing the manufacturing industry.